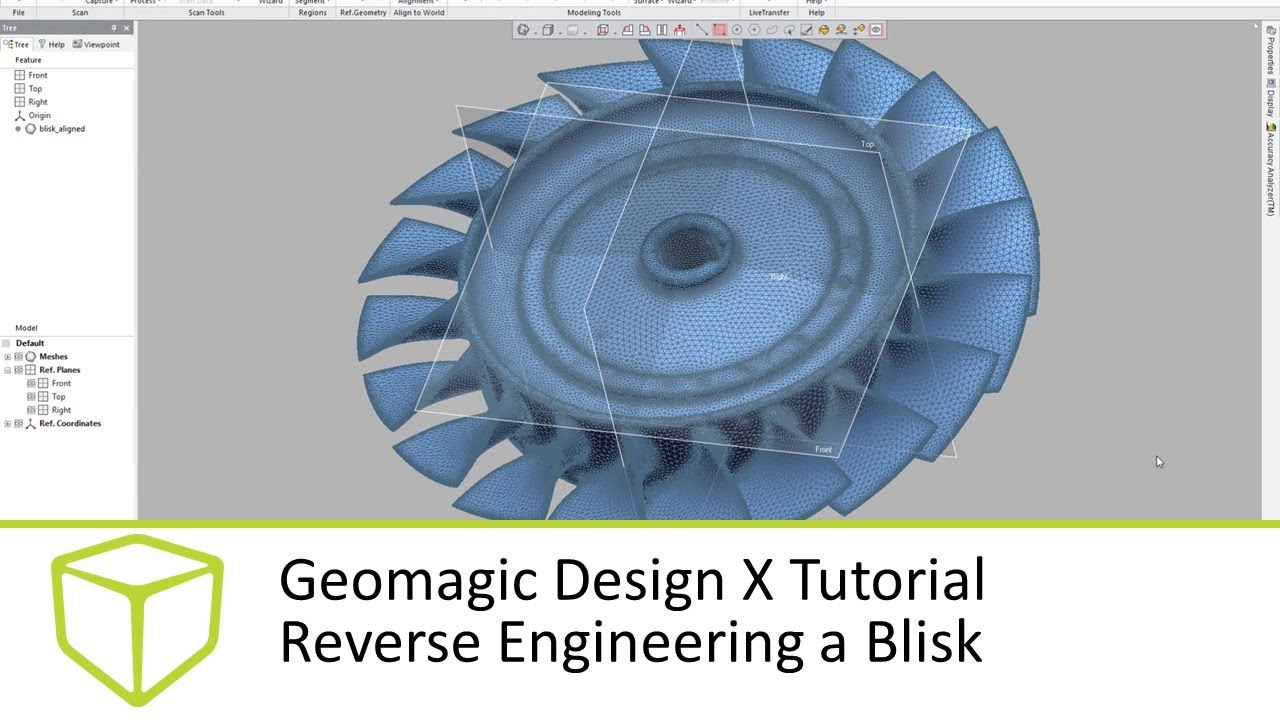

Among some of the settings were options to automatically remove outliers, clean noise and generate a mesh as the physical part is being scanned. One aspect to be aware of is when moving between the dark and light material areas of the AT901, these areas required a quick adjustment to the arm sensor’s exposure setting (by holding both side buttons for three seconds). Along with audio feedback from the Romer Arm this made the data acquisition extremely user friendly. The live onscreen feedback given by LiveScan™ is very useful, as it highlights the current scan pass so you can easily identify the next area that requires scanning. Using our Romer Absolute 7535SI portable scanning arm PES was able to move around the Leica AT901 laser tracker, scanning all the surfaces to capture the required data for a complete point cloud. This means that the user does not have to switch between software packages for scanning and modelling. Data Acquisition LiveScan™ is a great feature of Design X as it allows the user to directly capture of point cloud data into Design X. This workflow took approximately 90 minutes to complete. In this tutorial PES will highlight features of Design X 2016, which have been used to scan and create a surface model of our Leica AT901 laser tracker. Scanning and reverse engineering are highly effective and powerful tools for capturing and digitally recreating physical objects.

PES are proud to present this tutorial video that covers laser scanning, meshing, data cleaning and surface modelling. Our team of engineers provide software demonstrations nationwide to a variety of industries for component inspection, reverse engineering, 3D printing and product design.

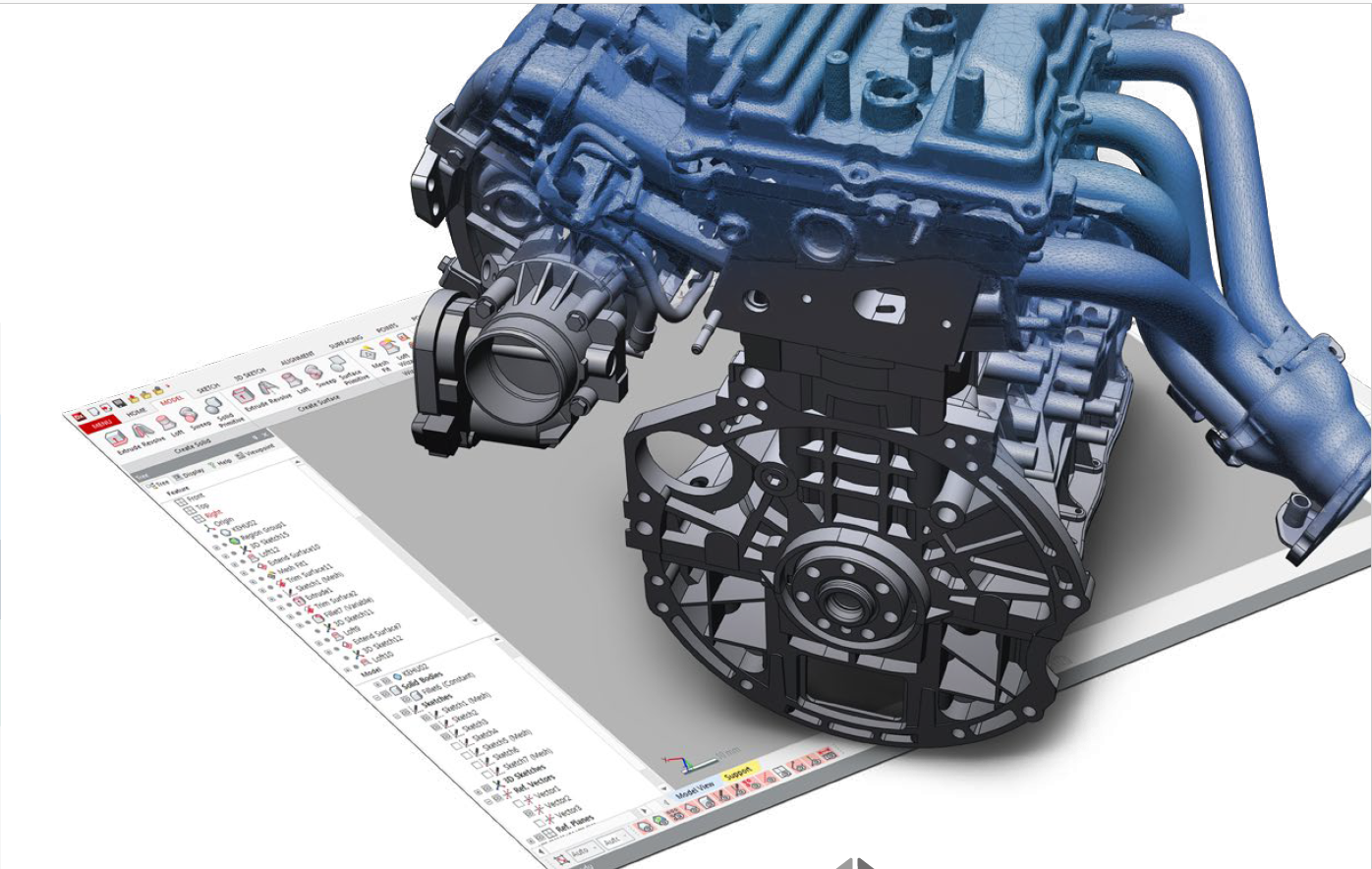

I tried to highlight not-really-obvious stages of mesh-to-CAD workflow.Introduction PES Metrology ( is a UK distributor of the Geomagic product range. To fight this prejudice, I made a tutorial on practical application of 3D scanner Calibry in reverse engineering. It is generally accepted that mesh-to-CAD conversion is tedious and hard. CAD model (on the left) and scanned mesh (on the right) Geomagic Design X was specifically designed for mesh-to-CAD transformation and provides powerful tools to achieve that result. Most CAD software (Autodesk Inventor, Autodesk Fusion 360, SolidWorks, Solid Edge) don’t have mesh-to-CAD support. A CAD model, converted from a mesh, is used for downstream applications such as 3D printing or manufacturing.

One of the most widely used spheres of application of 3D scanners is reverse engineering.

A 3D scan is only an element in the production chain.

0 kommentar(er)

0 kommentar(er)